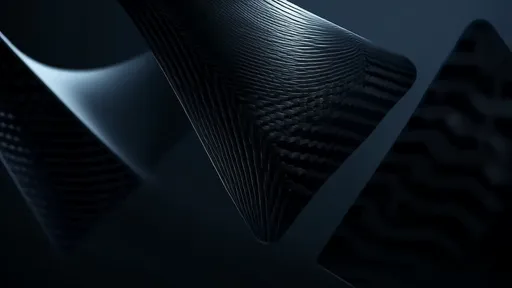

In the quiet laboratories and humming manufacturing facilities across the globe, a silent revolution is unfolding. High-performance carbon fiber composites, once the exclusive domain of aerospace and elite motorsports, are now spearheading a profound transformation within the advanced materials industry. This shift is not merely about replacing metals; it is about redefining the very possibilities of design, engineering, and sustainability across a breathtaking array of sectors.

The fundamental allure of these materials lies in their extraordinary strength-to-weight ratio. A structure made from carbon fiber composite can be as strong as, or stronger than, its steel counterpart while being up to 70% lighter. This characteristic, combined with exceptional stiffness, corrosion resistance, and fatigue performance, makes it a game-changer. For decades, the high cost of precursor materials and complex, energy-intensive manufacturing processes confined their use to applications where performance utterly outweighed expense. However, that paradigm is crumbling.

Aerospace has long been the proving ground, and here, carbon fiber composites are now the undisputed backbone of modern aviation. From the wings and fuselage of the Boeing 787 Dreamliner to the entire airframe of the Airbus A350, these materials have enabled unprecedented fuel efficiency, longer ranges, and reduced maintenance costs. The success in aerospace provided the initial validation and spurred intensive research and development, driving down costs and improving manufacturing techniques. This created a powerful ripple effect, allowing the technology to cascade into other, more terrestrial domains.

The automotive industry is currently in the throes of this transformation. In the high-stakes world of Formula 1 and hypercars, carbon fiber monocoques have been standard for years, providing unparalleled safety and performance. Now, the trickle-down effect is reaching mass-market electric vehicles. For EVs, reducing weight is directly correlated with extending range—the single most critical metric for consumer adoption. Using carbon fiber for body panels, chassis components, and even wheels allows automakers to either increase battery capacity without adding weight or achieve the same range with a smaller, less expensive battery pack. This economic calculus is fundamentally altering material selection strategies in Detroit, Stuttgart, and Tokyo.

Beyond moving people and goods, carbon fiber composites are making significant inroads into the realm of sustainable energy. The blades of modern wind turbines, which now stretch well over 100 meters, are almost exclusively constructed from these advanced composites. Their light weight reduces the load on the turbine's hub and drivetrain, while their durability allows them to withstand decades of punishing environmental stress. Without the properties of carbon fiber, the scale and efficiency of contemporary wind power would be unattainable, making it a critical enabler of the green energy transition.

The sporting goods and consumer product sectors have also been early and visible adopters. From tennis rackets and golf club shafts that offer perfect synergy of power and control to bicycles that are featherlight yet incredibly robust, carbon fiber has become synonymous with high performance. In the luxury goods market, it signifies a blend of high-tech appeal and rugged elegance, appearing in everything from watch cases to luggage. This broad consumer exposure has helped demystify the material and create a market pull that further incentivizes production scaling.

Perhaps the most profound shift is occurring in the industrial and infrastructure sectors. The use of carbon fiber-reinforced polymers for strengthening bridges, buildings, and historical monuments is a rapidly growing field. Unlike traditional steel plates, carbon fiber wraps are lightweight, non-corrosive, and can be applied with minimal disruption, dramatically extending the service life of critical infrastructure. In the oil and gas industry, carbon fiber pipelines are being deployed for their resistance to harsh chemicals and high pressures, reducing maintenance downtime and environmental risks.

The engine of this widespread adoption is a dual-front advancement in both materials science and manufacturing technology. On the materials front, researchers are developing new types of carbon fiber from alternative precursors, such as lignin from biomass or recycled plastics, aiming to lower costs and improve sustainability. The development of thermoplastic carbon composites, which can be reheated and reformed, promises a future with fully recyclable carbon fiber components, addressing a key environmental concern.

Simultaneously, manufacturing processes are evolving at a breakneck pace. Automated fiber placement and automated tape laying machines are drastically reducing the labor time and cost associated with laying up composite parts. Out-of-autoclave curing techniques are enabling the production of large, high-performance structures without the need for massive, energy-guzzling pressure ovens. Additive manufacturing, or 3D printing, with continuous carbon fiber filaments is opening the door to complex, optimized geometries that were previously impossible to produce, heralding a new era of digital fabrication.

However, the path forward is not without its challenges. The high energy cost of producing the primary precursor, polyacrylonitrile (PAN)-based carbon fiber, remains a significant hurdle. The recycling of thermoset composites, which make up the bulk of current structures, is still a complex and costly process, though intensive research is yielding promising solutions. Furthermore, qualifying these new materials and processes for safety-critical applications in aviation and automotive industries is a rigorous and time-consuming endeavor.

Despite these hurdles, the momentum is undeniable. Global market forecasts consistently project robust growth for the carbon fiber composites industry, driven by demand from aerospace, automotive, wind energy, and an expanding list of other sectors. National governments and major corporations are investing billions in next-generation production facilities and R&D programs, betting on a composite-intensive future.

In conclusion, high-performance carbon fiber composites are far more than just another new material. They represent a foundational shift in industrial capability. By enabling lighter, stronger, and more durable products, they are directly contributing to increased energy efficiency, reduced emissions, and enhanced performance across the global economy. The transformation they are leading within the new materials industry is not a fleeting trend but a fundamental recalibration of how we build our world, from the skies above to the roads below, pushing the boundaries of innovation and sustainability for decades to come.

By /Oct 21, 2025

By /Oct 20, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By William Miller/Oct 20, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 20, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By Joshua Howard/Oct 20, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 20, 2025